Our Facilities

As a high-pressure (1440 psi Maximum Allowable Operating Pressure [MAOP]) interstate natural gas transmission pipeline, Iroquois transports clean-burning natural gas from a variety of supply locations to other transmission pipelines, power plants, industrial users, and local distribution companies who then deliver it to residential and commercial users.

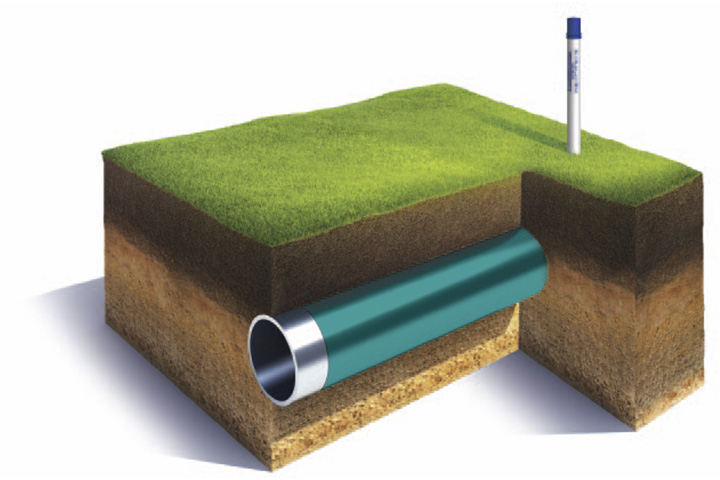

Pipeline

Iroquois’ transmission pipeline is buried underground at a depth that meets or exceeds pipeline safety regulations. The pipe itself is made of high-strength micro-alloyed steel with a designed wall thickness to meet stringent federal regulations for specific locations and pressure of the pipeline. All welds were inspected both visually and with radiographic equipment by a third party expert, and then the pipeline was coated with a fusion-bond epoxy coating engineered to resist corrosion and provide a waterproof barrier between the steel pipe and the external environment.

Before being placed into service, the pipeline was tested by pressurizing it to higher than the maximum allowable operating pressure.

Compressor Stations

Compressor stations along our pipeline are strategically placed to boost natural gas pressure to counter pressure lost through friction as the gas travels through the system, or as it is transported to various delivery points. Many of our compressor stations also have cooling facilities that use electric-motor-driven fans designed to cool the gas as it leaves the compressor station. The coolers keep temperatures within safe operating conditions and enable more volume to flow back into the pipeline.

Meter Stations and Automated Valves

Meter stations measure gas volumes at each delivery point on our system. Automated valves control gas flow through the pipeline, and can be operated locally by a trained technician, remotely by gas control, or automatically based on pre-determined set points, enabling quick shut off of the pipeline should an emergency arise.

Pipeline Maintenance Activities

Our compressor station operators and field engineers continually perform an array of surveillance and maintenance tasks to ensure the continued safe operation of our system.

In the event that Iroquois schedules maintenance or other activity that may cause loud noise or odor to be detectable by residents within close proximity of the pipeline, notice, and updates for such may be provided here.

2025 Scheduled Maintenance - Pipeline Internal Monitoring

If you have any questions regarding this work, please call Iroquois’ non-emergency hotline at 1-800-253-5152. If you have a safety concern during the planned activity, please call Iroquois’ Gas Control Center at 1-800-888-3982.

In-Line Inspection Schedule* - Gauge Tool

| Date | Time | Location | Activity | Status |

|---|---|---|---|---|

| Monday, April 21 | Morning | Northport, NY | Insert Tool | Completed |

| Wednesday, April 23 | Morning | Hunts Point, NY | Extract Tool | Completed |

In-Line Inspection Schedule* - Smart Tool

| Date | Time | Location | Activity | Status |

|---|---|---|---|---|

| Thursday, April 24 | Morning | Northport, NY | Insert Tool | Completed |

| Saturday, April 26 | Morning | Hunts Point, NY | Extract Tool | Completed |